ThermoDrive V2 – a new generation of fasteners for fixing thermal insulation by Klimas Wkręt-met

ThermoDrive V2 by Klimas Wkręt-met is a series of a new generation of universal fasteners for fixing polystyrene, mineral wool, and wood wool, with unprecedented tolerance to inaccuracies of thickness and surface of insulation and substrates present in the realities of construction. Their parameters and high load-bearing capacity values qualify them for fixing a very wide range of ETICS systems, including on buildings undergoing thermal modernization – “ETICS on ETICS”.

Mechanical fasteners perform a few functions in external wall insulation. One of these is load transfer, primarily protecting the ETICS system from wind suction forces and detachment from the substrate. Mechanical fasteners have the task of stiffening the entire insulation system, eliminating movement and deformation of individual insulation boards, limiting the formation of point thermal bridges, or protecting against failure due to loss of adhesion and load-bearing capacity of the adhesive layer with the substrate. These are the basic parameters that should be met by mechanical fasteners in ETICS insulation systems.

– In Klimas Wkręt-met we go a step further and introduce a new generation of ThermoDrive V2 connectors, which, maintaining the required parameters, thanks to their construction can be used for attaching polystyrene and mineral wool to, among others, substrates made of concrete, solid ceramic brick, ceramic hollow brick, elements made of lightweight aggregate and cellular concrete. In addition, it will perform excellently in the massively uneven substrates encountered in the realities of construction, including those contaminated with old layers – says Paweł Polak, Global Product Manager at Klimas Wkręt-met

Unique ThermoDrive V2 construction

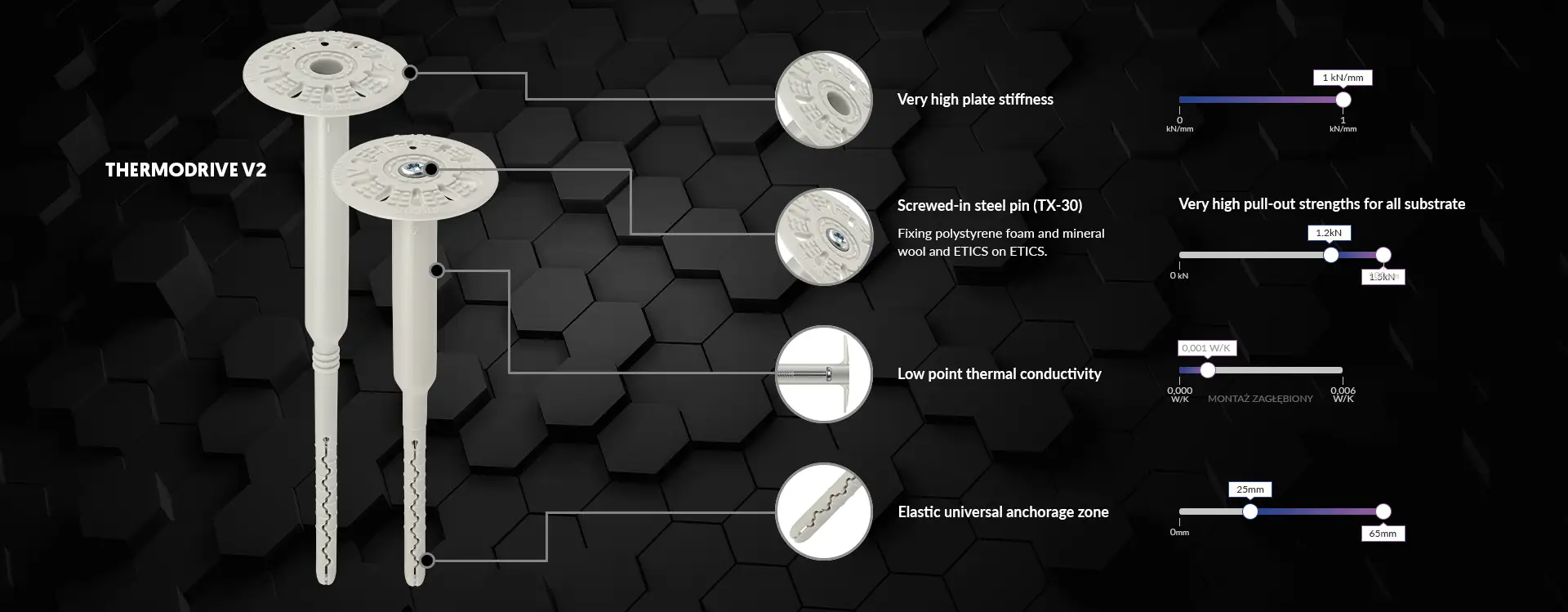

The ThermoDrive V2 connector owes its versatile performance to its unique design. The advantages of the well-known and appreciated products from the WKTHERM-S series and the ECO-DRIVE series have been integrated and enhanced into this solution. They are characterized by easy and secure installation, reliability, and versatility of use, as well as the maximum achievable pull-out load.

Regardless of the chosen installation method, the fastener can be used effectively for a wide range of insulation thicknesses up to and including 40-some cm. In addition, the unprecedented wide tolerance range for uneven substrates on the market entitles the ThermoDrive V2 is to be effectively installed in very uneven substrates. As a result, it can be used for a variety of substrates within a single project, so, for example, solid and hollow materials side by side using only one fastener length.

Guaranteed robustness

In addition, the design of the 25-65 mm universal anchorage zone guarantees a solid anchorage of the fastener even in hollow materials with hollow centers and thin walls of the internal structure of the masonry element.

– Until now, even fastener sizes of a few centimeters longer in a similar class did not guarantee such an effective anchorage, due to the shorter and limited anchorage zone and the greater likelihood of missing the anchorage zone into the thin walls of the internal structure of the masonry element, explains Paweł Polak. – The ThermoDrive V2 fastener is successfully suitable for the mechanical fixing of ETICS (and ETICS on ETICS) during the renovation of external walls of buildings made with large slab technology. From a formal point of view, it can be used in a concrete ‘texture’ layer with a minimum thickness of 40 millimeters, achieving high strength parameters. This is all thanks to the achievement of sufficiently high parameters, demonstrated during the certification process. It should be mentioned that more than 90 percent of façade connectors so far on the market do not have this capability, comments the expert.

ETICS contractors and system providers will appreciate the very high rigidity of the plate, which increases the durability and safety of the insulation systems. The sleeve of the fastener has been designed in such a way that the screwed-in steel pin, which enables the insulation layer to be fixed, is sufficiently insulated. As a result, the ThermoDrive V2 is characterized by a minimum point thermal conductivity coefficient. Particularly noteworthy for a metal shank fastener with such a wide range of applications is the fact that the point thermal conductivity value of only 0.001 W/K – applies irrespective of the thickness of the insulation to be fixed to the substrate.

Klimas Wkręt-met, which has been present in the Polish construction market for more than thirty years, has made a significant contribution to the development of the entire sector. The launch of ThermoDrive V2 is proof that the company is actively working on the evolution of a group of mechanical fastening systems for thermal wall insulation, compatible with the requirements of various ETICS insulation systems. It is also actively involved in organizations such as the National Association for Thermal Insulation Systems or the European Association for Composite External Thermal Insulation Systems – EAE and the French Association Le Mur Manteau, which ensure the dissemination of complete technological solutions with documented quality.