Insulating a building from the outside guarantees the warmth of its inhabitants and a significant reduction in heating costs. Thanks to a properly made insulation system, the house gains good thermal insulation, which also minimises its heating during hot weather.

What is wall insulation – ETICS systems

Insulating external walls is a way to make buildings more energy efficient. A well-insulated house not only means low energy losses and reduced heating costs, but above all it is an interior that is warm in winter and cool in summer, as the most important task of insulation is to protect, both thermally and from adverse environmental conditions such as noise. This poses many challenges for thermal insulation producers. Meeting stringent requirements, faultlessness or a guarantee of durability for years are also paramount with regard to fasteners. External wall insulation is carried out by fixing a layered insulation system, with each layer having a specific function in the system.

Substrate preparation

The durability of the entire insulation system depends on the quality of the substrate. Therefore, attention must be paid to its assessment and preparation. It is important to remember that an old house is insulated in a different way than a newly built one. That is why, before insulating an old building with masonry walls which are not plastered, it is necessary to rinse with a stream of water and fill cavities and too deep gaps between bricks, blocks or hollow bricks with mortar. The wall should always be primed.

From the wall covered with plaster, all dirt must be removed. If it is damp or mouldy, the cause of this condition must first be removed. Cracked or loose plaster is removed. In new buildings, cleaning the walls is sufficient without renovation work.

Installing the thermal insulation layer (insulation)

Ground floor of the building. The foundations are insulated after the vertical insulation has been completed. The plinth part of the building is separated from the facade by the so-called starting profile – starting strip. Below ground level, the insulation of basement walls is made from polystyrene foam with a higher density. This protects the waterproofing against mechanical damage from backfill soil pressure.

Building wall. Insulation methods vary depending on the type of building material used to erect the building (timber, brick or frame houses). The basic methods of insulating walls from the outside are:

- insulation of walls in ETICS systems

- insulation in a ventilated facade system

Klimas Wkręt-met fasteners in ETICS systems

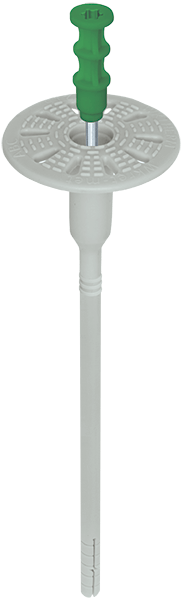

The innovative fastener for fixing wall thermal insulation is a combination of several features that together guarantee efficient and safe installation and durability of the entire ETICS system.

Trouble-free and failure-free? FIXPLUG!

Fasteners in thermal insulation systems must be characterised by their multifunctionality. One of their tasks is to transmit the relevant pulling forces from the substrate, which are caused by the suction forces of the wind. In addition to this, the fastener must prevent the thermal insulation material from pulling through the fastener pressure plate; it should adequately press the material into the substrate, stiffen the entire system and ensure proper point thermal conductivity. The thermal insulation fastener should reduce the formation of thermal bridges at the installation points; their important feature is also to protect the entire insulation system from failure, which may be caused by loss of adhesion or load-bearing capacity of the adhesive layer, and to compensate for forces arising on the facade as a result of diurnal temperature variation.

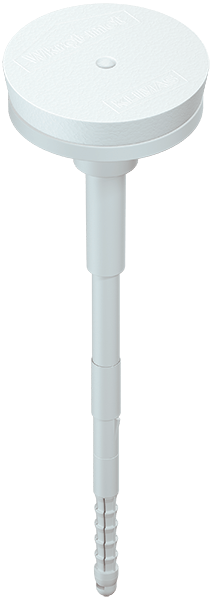

FIXPLUG meets all these requirements. The fastener has a fibreglass-reinforced plastic nail, which makes it very strong and does not break during installation, even when hammering. The telescopic design of the FIXPLUG fastener ensures that it is properly embedded in the substrate and that the pressure flange is sunk into the insulation material, making it considerably easier to lay the reinforcement mesh on the facade. In addition, there is no need for a thick layer of adhesive to level the surface and hide the fastener pressure flanges that are not flush with the thermal insulation material. The installation is seamless and trouble-free.

The fastener is also characterised by a special 4-way embedment depth design, thanks to which it achieves very high load-bearing capacity and guarantees secure fixing of polystyrene foam in materials in all substrate categories (ABCDE) according to ETAG014: concrete, solid and hollow masonry elements, aerated concrete, concrete elements on lightweight aggregates. Thanks to the design of the embedment depth and the reinforced nail, the load bearing capacity of the fastener is comparable to that of fasteners with a metal nail. Its ease of use is increased as the FIXPLUG fastener is supplied complete (pre-assembled).

WKTHERM 8 and WKTHERM S 8

The WKTHERM 8 hammer-in and WKTHERM 8 S screw-in fastener with metal nail and short embedment depth, which allows for maximum fastener strengths with minimum effort and equipment costs. The fastener is designed for fixing polystyrene foam and mineral wool in substrates such as concrete, solid ceramic and silicate brick, ceramic hollow block.

The special elongated head of the metal nail is covered with plastic which protects it against corrosion.

The WKTHERM fastener sleeve is designed to increase the rigidity of the holding plate. The fasteners are pre-assembled: this ensures that the fastener components are always correctly matched.

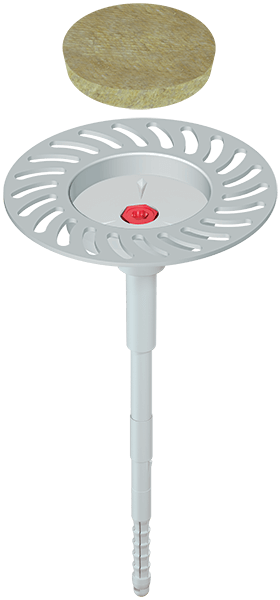

ECO-DRIVE 8, ECO-DRIVE S 8 – for polystyrene foam, ECO-DRIVE W – for mineral wool

Universal screw-in fastener with metal nail and telescopic holding plate for attaching polystyrene foam to lightweight materials such as ceramic hollow block or aerated concrete – screwing in the nail prevents the structure of the substrate from breaking down and guarantees the highest strength parameters.

By combining a telescopic design with a plate that cuts the thermal insulation material, the installation time is reduced. For the sake of the environment, the product does not require the use of the WK-FT plastic cutter (during recessed installation) – this completely eliminates the problem of environmental pollution caused by polystyrene foam dust.

The fastener is designed for recessed installation. It is fitted with a system polystyrene foam plate. This eliminates the formation of point thermal bridges and improves the aesthetics of the external layer of insulation.

Proven products will certainly make the whole undertaking easier, and the final effect will be pleasing not only to the eye, but also to the pocket. Before getting down to work, one only has to remember to select the right products and technologies, as well as a contractor. It is important to follow the producer’s recommendations and carry out the work properly so that we can enjoy the cold in the summer and spend the long chilly evenings in our magical home in the winter months, where it will be warm, safe and quiet.

Wall insulation – what to look out for:

- old buildings – where renovation is being carried out and new buildings, in which the insulation has usually been designed during the construction process

- substrates – in new buildings they are usually not a problem and only need to be cleaned of any dirt. The trouble arises with old buildings, which are often covered with weakened plaster, dirt, moss or other tarnish. In such cases, it is necessary to remember about proper surface preparation, as the consequence of poor wall preparation may be detachment of the entire insulation system.

- thermal insulation material – polystyrene foam or mineral wool

- thickness of thermal insulation – the parameter which describes thermal insulation properties of the whole partition is the heat transfer coefficient (U). The lower its value, the better the thermal insulation. This coefficient depends primarily on the thickness of the materials of which the partition is composed and their properties described by the thermal conductivity coefficient – lambda. The lower the lambda of a material, the better its thermal insulation properties. On the other hand, the thicker the insulation layer, the lower the heat transfer coefficient.

- surface or recessed installation of fasteners – this stage of work is important because it has a direct impact on the point heat transfer coefficient through the partition.

Important!

- Using the wrong fastener can result in additional thermal bridges.

- Too few fasteners used can weaken the system in the event of failure.

- If the fastener is installed too deep in the thermal insulation layer and then glued with a larger amount of adhesive, the facade will show visible points of the so-called “ladybug effect”, which results in an unsightly appearance of the facade when the temperature changes rapidly and the air humidity is high.

- In the edge areas (building corners and around window and door openings), the number of fasteners should be increased.

- The installation of the fasteners should be carried out at least 24 hours after the insulation panel have been glued in place.

- Work should be carried out in a temperature range of +5 to +25°C.

- The fastener installation should be in the adhesive zone for fixing the thermal insulation panel.