For what purpose should mechanical fasteners be used to fix facade thermal insulation?

According to the European Assessment Document EAD 330196-01-0604 on plastic fasteners for fixing ETICS systems, their primary purpose is to provide additional protection for the insulation layer against wind suction forces (forces that pull the insulation system out of the building wall). The fasteners also transfer thermal loads caused by the heating and cooling of the insulated facade. In addition, they protect against the consequences of inadequate preparation of the substrate for gluing the thermal insulation panels, such as lack of priming of the substrate or leaving behind old plaster or peeling facade paint. They provide high security for fixing the system through high resistance to pulling out of the substrate, as well as adequate plate stiffness and high parameters for pulling through the insulation material.

Other functions of the fasteners are to provide a low point thermal conductivity and to additionally stiffen the entire adhesive joint by increasing the friction forces between the individual ETICS layers. Please note that mechanical installation can take place at the earliest 48 hours after the thermal insulation panels have been glued to the wall.

Proper selection of the type of fastener

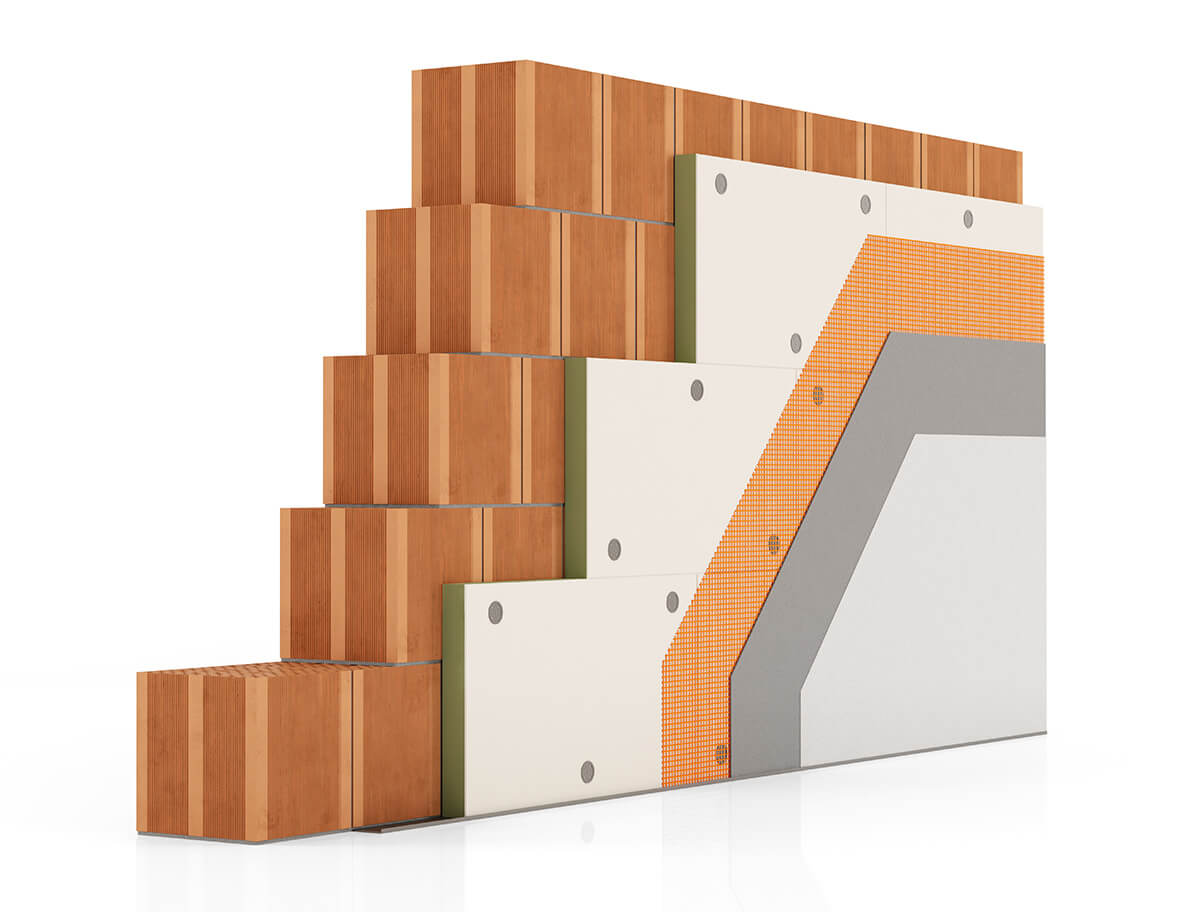

Mechanical connection of thermal insulation materials (made of polystyrene foam or mineral wool) to the structure of the external wall of the building requires planning and proper selection of fasteners depending on the type of substrate and thermal insulation material.

Substrate:

- First, you need to determine the type of building – whether it is to be a new-build or modernised building. For new buildings, it can be assumed that the thickness of the adhesive mortar connecting the polystyrene panels or wool to the wall substrate is approximately 10 mm. For modernised buildings, the type and condition of the substrate should be verified on site and its load-bearing capacity assessed (pull-out tests). The thickness of the old plaster should be determined and its adhesion checked, especially as complete detailed design documentation is often missing for older buildings.

- The next step is to determine the substrate category A, B, C, D or E to which the ETICS insulation system will be fixed, as defined in EAD 330196-01-0604 – European Assessment Document “Plastic fasteners for fixing of external thermal insulation composite systems” (or in ETAG 014 – Guidance for European Technical Assessments). The new generation of fasteners is designed to meet the strength requirements in all substrates (Classes A, B, C, D, E), so there is no need to use different fasteners for different substrates on the same building.

| A | B | C | D | E |

|---|---|---|---|---|

|  |  |  |  |

| Concrate C12/15 C16/20 do C50/60 | Ceramic solid brick, silicate solid brick | Silicate hollow brick KSL, ceramic hollow brick HLZ, porous hollow block, ceramic hollow block | Lightweight aggregate components LAC | Autoclaved aerated concrete AAC2, AAC 7 |

Thermal insulation material:

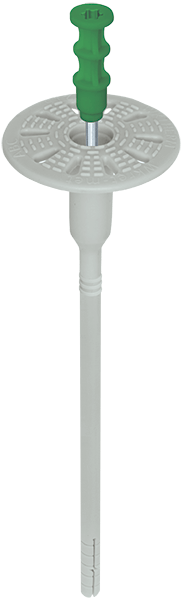

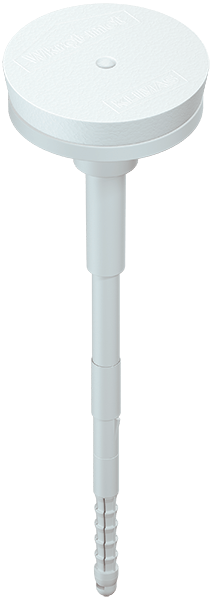

- Then, depending on the planned thermal insulation, the selection of fastener is made in terms of the nail material. For the fixing of EPS and XPS, white and graphite polystyrene foam, mechanical fasteners with plastic nail or metal nail, hammer-in or screw-in, are used. Only fasteners with a metal nail are suitable for fixing MW mineral wool insulation. For some ETICS systems based on mineral wool, e.g. lamella, their Technical Assessments also recommend the use of an additional holding plate with an enlarged pressure area of the thermal insulation to the substrate type TDX-90 or TDX-140 (mm). This solution is used to increase the fastener’s resistance to pulling the soft thermal insulation material through its plate.

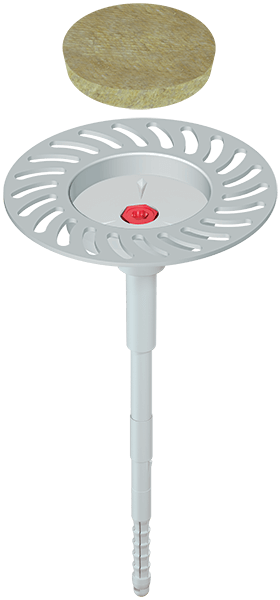

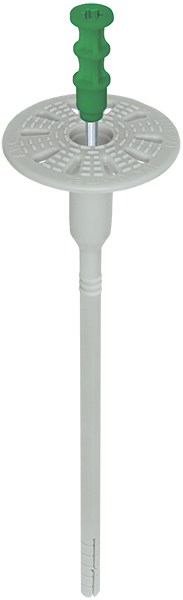

Plastic fastener with plastic nail – FIXPLUG

Plastic fastener with metal nail – WKTHERM S

- The thickness of the thermal insulation material is then determined.

- The method of fastener installation is important. The surface installation (visible) is characterised by the flush installation of the fastener plate with the surface of the polystyrene foam or facade wool. Recessed installation (concealed) involves embedding the fastener 20 mm into the thermal insulation and covering it with a ready-made cap made of suitable insulation material – under no circumstances should the adhesive residue be filled in. The recessed installation is carried out using a special plastic (for EPS) or metal (for mineral wool) cutter. This solution provides additional thermal protection for the building.

Selection of fastener lengths

The calculation of the fastener length is based on the summation of the thickness of the thermal insulation (in the case of recessed installation, this is 20 mm less), the thickness of the adhesive mortar, the thickness of any old plaster (in old buildings) and the effective anchorage depth of the fastener (value read from the product documentation may be different for each fastener).

Selection of the number of fasteners

The final step is to calculate the minimum number of fasteners for each m2 of facade insulation system. The number of fasteners depends on the dimensions of the building, its location, the category of terrain or wall material and the type of thermal insulation used. During the calculation procedure, which is carried out according to the wind standard for larger buildings, the facade of a particular building is divided into so-called wind zones, the wind pressure at each zone is checked and the number of fasteners for each zone is calculated. For small buildings, the recommended minimum number of fasteners is taken on a simplified basis, depending on the height of the building and the type of thermal insulation material of the insulation system.

The need for fasteners and their type, number and location should be defined by the technical design or the selected insulation system on the basis of the expected design loads. The number of fasteners is correspondingly increased for the facade edge zone by a minimum of 20% and a maximum of 50% (the width of the zone is conventionally defined in relation to 1/8 of the width of the narrower side of the building; it should be between 1 and 2 m).